Laser platform concept

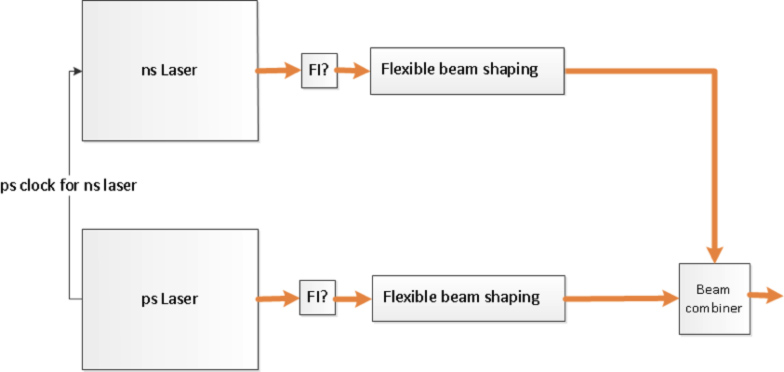

The initial plartform is made of two lasers with different pulse durations. In order to optimize the cost and the developement time, these are available from the shelves as standard products

One is a nanoseconde laser with a stronger thermal effect on the material. It is used for the metallic substrates like the aluminum.

The other laser is a pico seconde laser that has less thermal effect and therefore with be used on the composite parts in order to avoid to damage the surface when texturing.

Both beam are optically aligned and combined in order to "supply" one ouput beam. Laser can be triggered independently depending on the required material to process.

For the concept the average usefull power is 50 watts. More power (approx 1kw) will be required for the industrial demonstrator version.

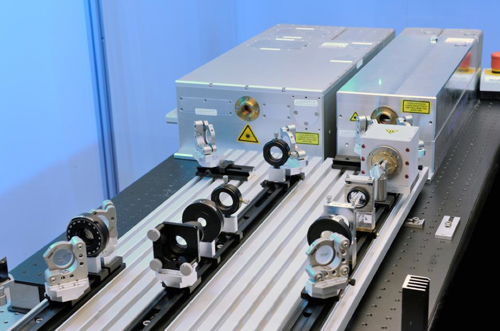

First approach

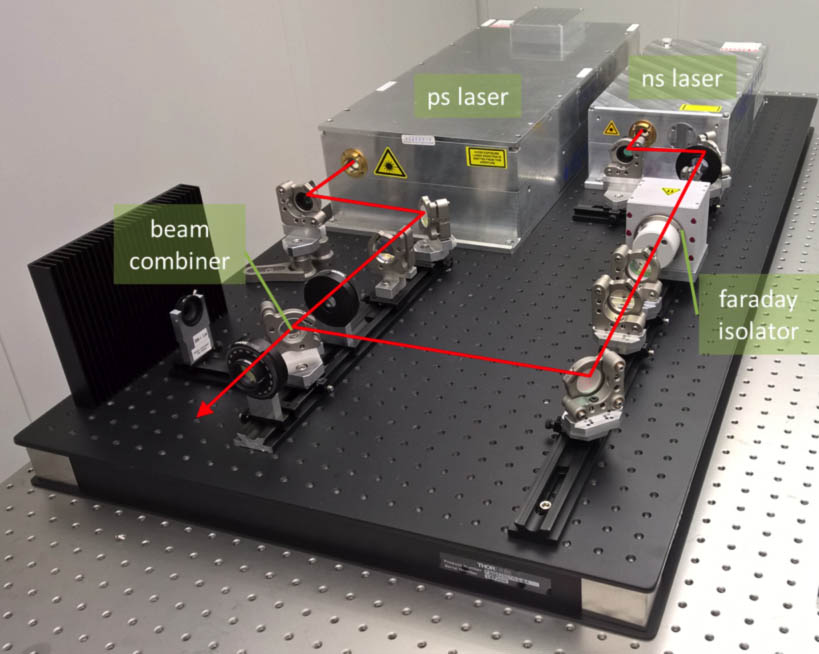

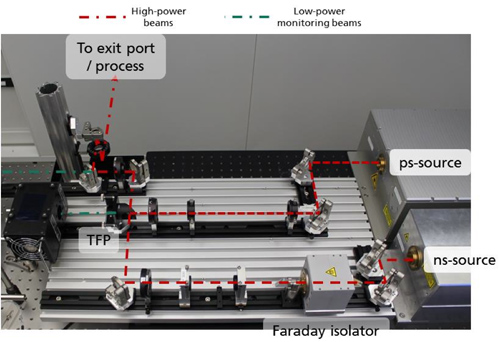

Final concept

Clic on the image to see the video presentation of the project

Final concept of the laser platform with the combination of the nano and pico lasers

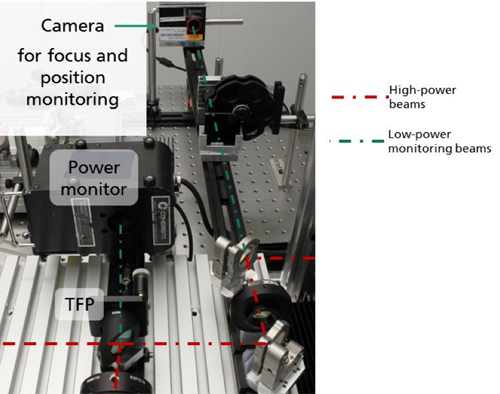

Close view of the optical bem combiner of the nano and pico lasers

Pointing Stabilty measuremenst device mounted on the laser platform

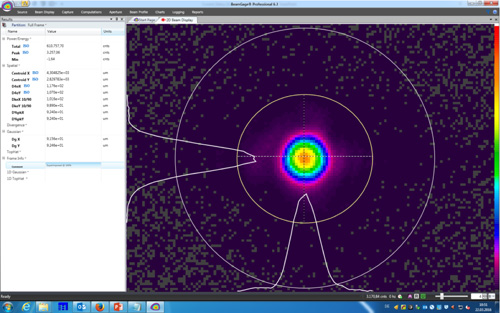

Printout of the two laser spots combined testes on the laser platform

Air Jordan 1 Blue Chill Womens CD0461 401 Release Date 4 | nike cortez mens on feet women images 2017