General overview of the concept

The EMLCAS project has proven that we can significantly increase the adhesion and the Deposit efficiency of Cold Spray by Laser texturing the substrate

The EMLACS concept has proven with remarkable results, that the adhesion of such coating by Cold Spray process can be improved up to a factor of 2 when the substrate has been laser textured before (80% for Al203/Cu powder, 105% for Pure Cu powder) !!

It will certainly open other process opportunities like thermal dissipation or thermal conduction on plastic/composite parts, protection of fragile surfaces where the cosmetic aspect has to be taken into consideration. Military industry will also be an area to investigate where components/modules are used in a very difficult environment conditions and where weight is also a major issue like in space applications.

Clic on the image to see the video presentation of the industrial housing EMLACS concept

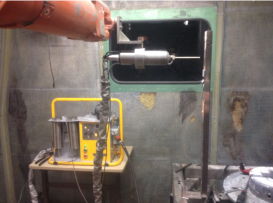

Industrial Laser platform adapted for the EMLACS proff of Concep based on a XYZ axes and Galvo head for Laser texturation

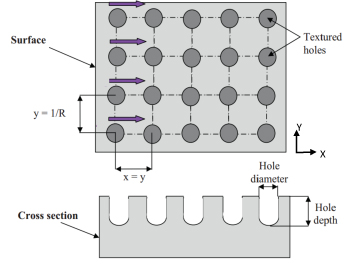

Laser Pattern rules and Cold Spray Setup

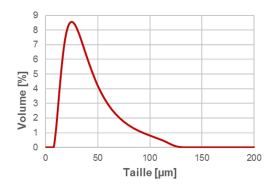

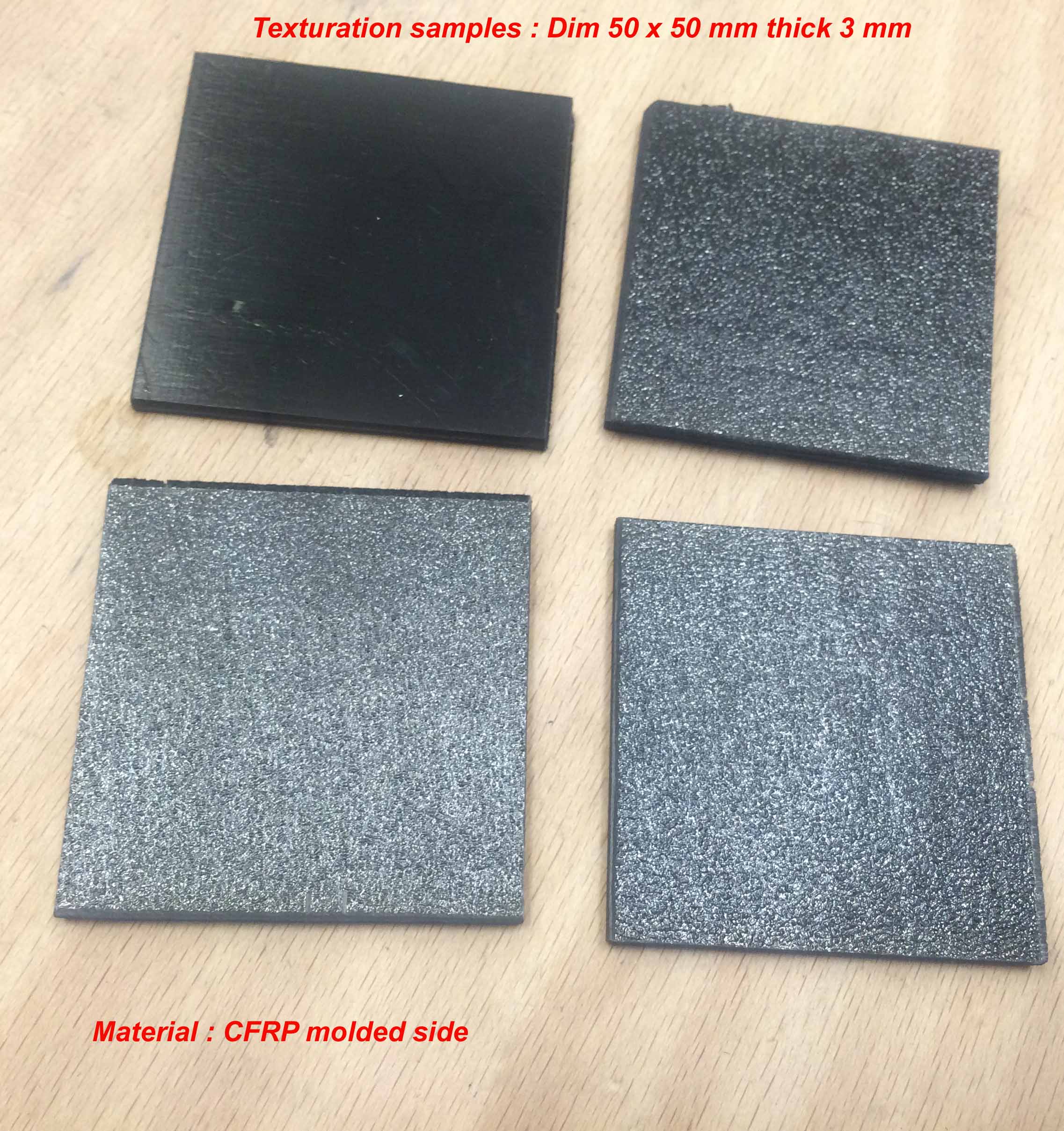

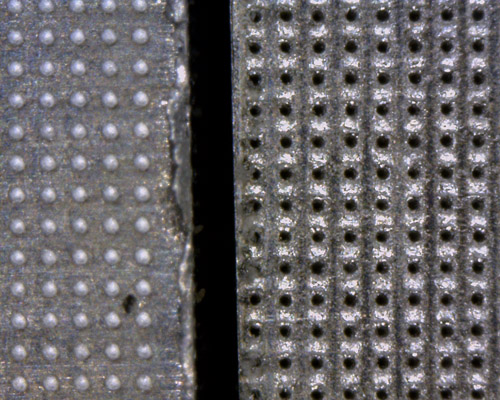

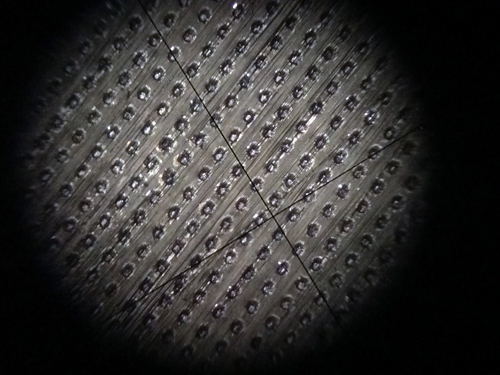

Laser patern texturation vs powder sizes

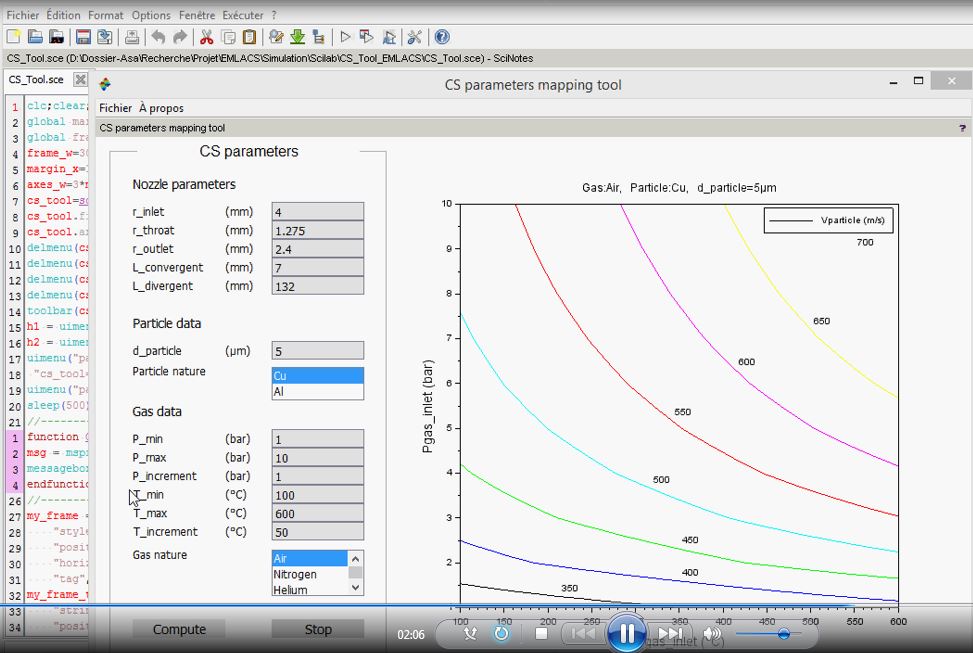

Cold Spray Simutaion Tool for the EMLACS technlogy

The Cold Spray simulation tools was developed in order to anticipate the coating process according to the environnemental paramaters.

Clic on the image to see the presentation vidéo

Cold Spray gun setup for the coating

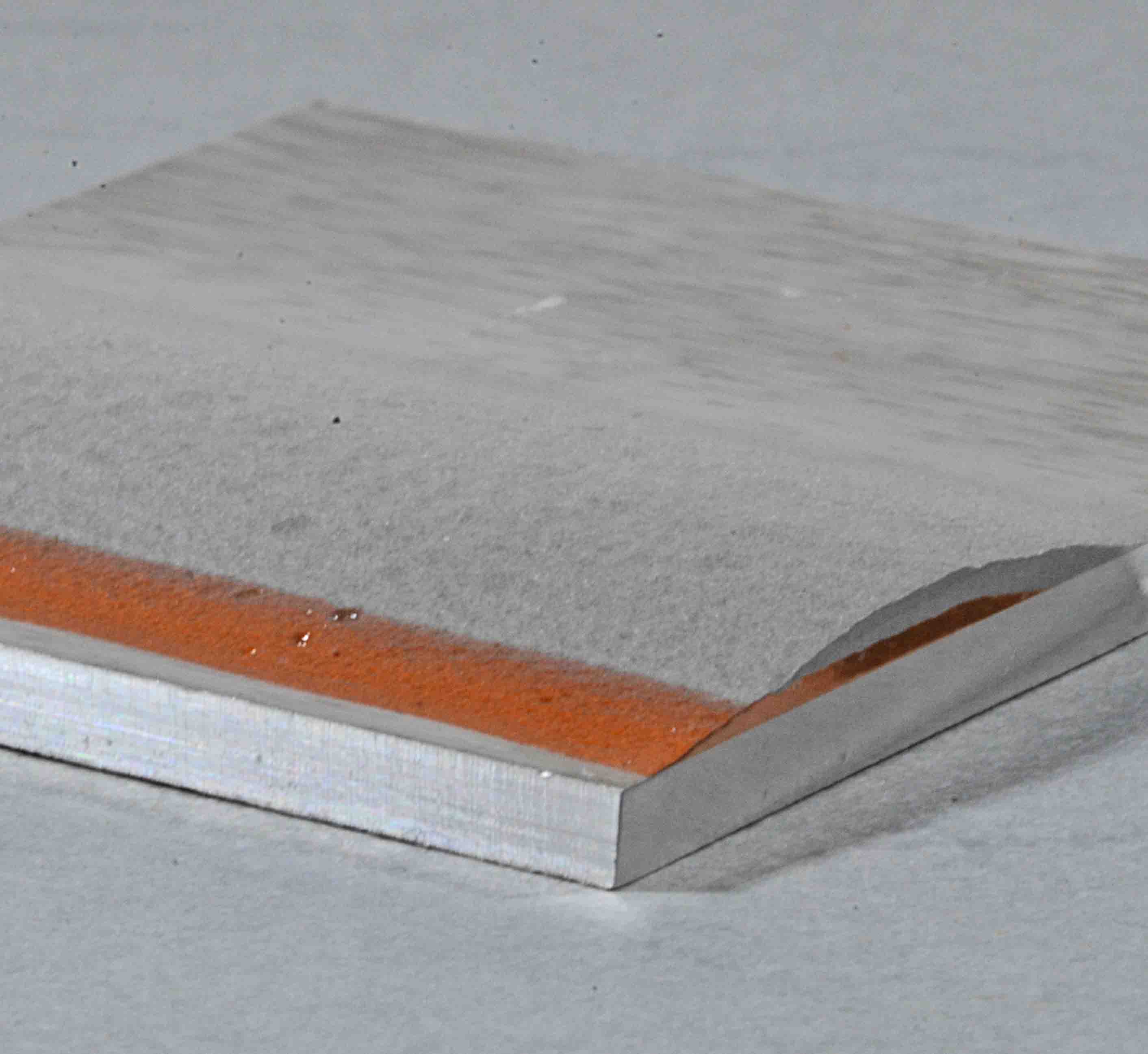

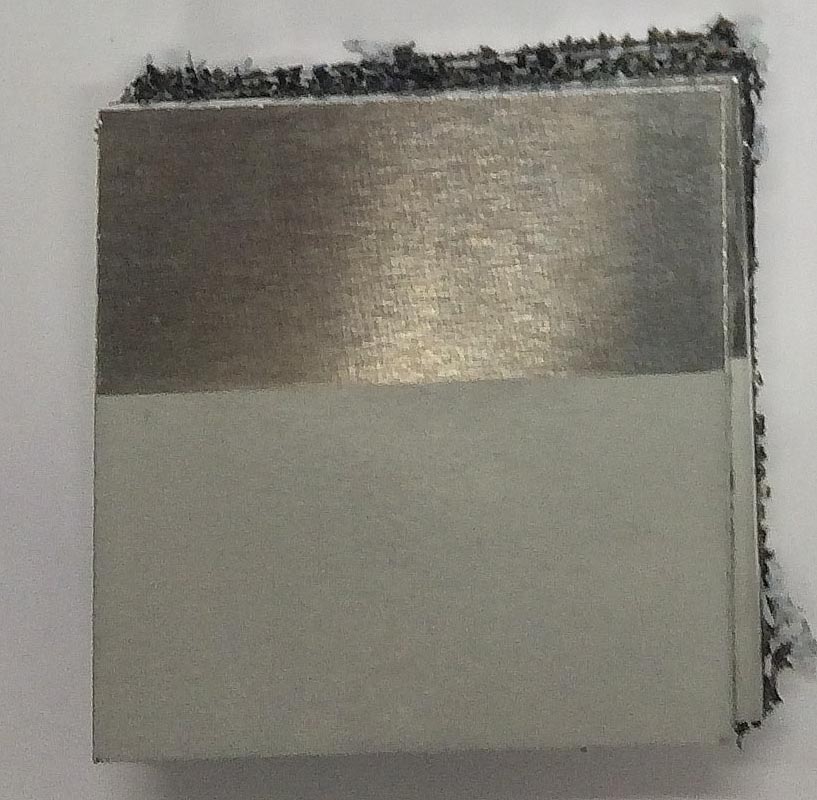

CFRP and Aluminum Samples laser texturated with Cold Spray Copper layers deposit

Substrates / raw materials

In order to prepare the surface of the different samples (laser texturation), we need to identify the right components, the right tools and the rigth elements to proceed.

The goal here is to proove that we can improve the D.E and the adhesion of Cold Spray coated parts by laser texturation of the surface.

The selected materials are Aluminum (automotive grade) and composite parts. Among the composite parts material, we have CFRP parts from the Aerospace industry and plastic parts from the automotive industry.

Aluminum pins for adhesion tests Samples half laser texturated CFRP samples

Aluminum and CFRP parts with Laser texturation prepared for Cold Spray

We identified the following setups :

a) The laser sources : nano seconde and pico seconde. (Edgewave)

b) The optical and electro-optical components to build the laser platform. The goal here is to combine both lasers in one. (Fraunhoffer ILT Institut)

c) The different components to build the online and offline vision system.

d) The hardware and software that will perform the image acquisition of the surface texturation

e) The cold spray system from Dycomet

f) The different powder materials for coating

g) The appropriate testing tools in order to mesure the Deposite Efficiency and the coating adhesion of the sprayed layers (done by the UTBM university)

h) Optimum Laser processing parameters according to the tests and mathematical model done also by the UTBM university

new nike football boots 2012 2017 - 002 - Nike Air Max 270 ESS Ανδρικά Παπούτσια Γκρι / Λευκό DM2462 | yeezy insole rubbing off wood stain floor